Your Cart is Empty

Lock picking as we know it is fun for anyone who dares to care. And as some refer to it, lock picking is an art that you must master, if you're ever going to attempt it. One of the oldest and truest forms of lock picking is the single pin technique, which is also our main topic for today.

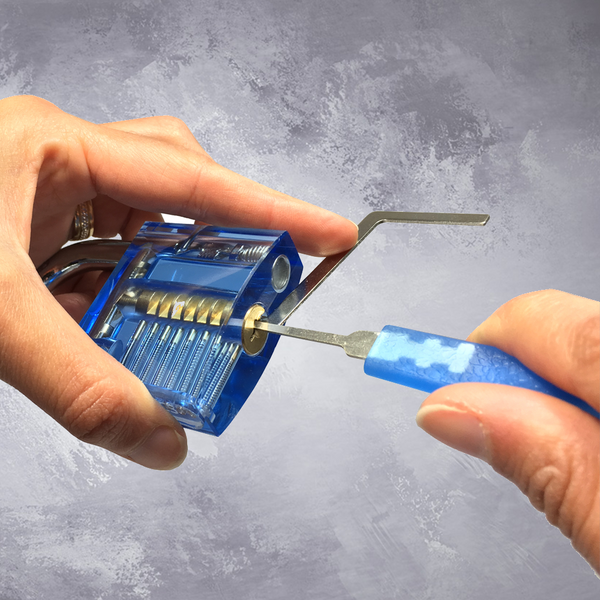

Single pin picking also referred to as SPP, is a method you can use to break open any tumbler lock. Just as any form of art would call for, SPP demands that the picker understands what is happening inside the lock throughout the picking process. If you haven't mastered SPP yet, you could practice raking instead as we shall see later.

The key to any game is understanding the rules. Similarly, your success at single pin picking is heavily tied to understanding a tumbler lock's components, for example, and knowing what principles can be manipulated.

The various components of any mechanism play different roles. Below are the multiple parts of a tumbler lock. Follow along and discover how they work, and you may not need anyone to train you how to pick a lock like this one.

Different Parts

This is how the different components of a lock constitute the locking mechanism:

1.Shell

The shell is the main exterior part, making up the lock's body and accommodating the plug.

2.Plug

As the name suggests, this is where you insert the key. The plug has a cam attached at the back end so as the plug rotates, it throws the bolt open or retracts the latch. This is basically how the lock opens. The plug rotates inside the shell at the shear line where the two parts articulate.

3.Pin chambers

Although these aren't parts as such, they can't be foregone. They are chambers bored through the shell on one side and into the plug. The pins are located inside these chambers. The specific interplay of the pins and their respective chambers is unique to the lock's key.

4.Key pins

Every chamber has two pins. The pins that come into contact with the key are called key pins. These pins are of different lengths and rest inside the plug down the shear line. The length of each key pin corresponds to the profile of the key when fully inserted. A shorter key pin would conform to a raised contour on the key, at the chamber where that pin sits. A shorter key would also need to be raised through a shorter distance to shear.

5.Driver pins

In a locked state, driver pins sink into the plug to the point where the opposing key pins reach. This way, the driver pins prevent the plug from rotating by blocking the shear line. Typically, the driver pins are of equal lengths. But this is not the case with higher quality locks. In such cases, the driver pin's length corresponds to the opposing key pin. This makes the lock very hard to decode.

6.Springs

The springs sit in the chambers between the chamber bottom in the shell and the driver pins above them. The springs return the key pins to the locking position when the key is withdrawn. The springs also keep the driver pins crossing the shear line, even when the lock is placed by its side.

So, how do you manipulate the inner workings of the lock to bypass it? Let's see that next.

As you already know, when you're a lock picker, you would manipulate the imperfections on the various components of the lock, to force the latter to open without the proper key.

When the key is inserted, it lifts the key pins, pushing against the driver pins. The correct key pushes the key pins by the required distances to align their contact points with the shear line's driver pins. This way, the plug can rotate freely in the shell, unlocking the lock. This is what the single pin picking method revolves around.

Lock picking typically involves two parts, or better in this case, tools. The first lock picking tool simulates the right key's insertion, lifting the key pins, and thus setting the plug free. The other is a tension tool, popularly referred to as a wrench, which imitates the proper key's turning motion when rotated.

The loophole...

When the correct key is inserted, it concurrently pushes the key pins to their proper heights. This would be an extremely difficult feat to undertake without the key, but that's not exactly the case.

The engineering tolerances on these lock components allow the pins to be manipulated individually, which in unfortunate situations, allows intruders in. secondly, a mass production line can never make mass machined components to the same lengths. This, in turn, causes a binding effect.

The chambers have varying diameters, are misaligned, and often not perfectly circular. The pins are no different. Although these imperfections may not be perceivable by the naked eye, they are present even in high-quality locks.

Due to the machining imperfections, only a single pin binds against its chamber when a torque is applied to the plug. All the pins would bind simultaneously if the entire lock were machined to perfection.

When the torque is applied, the pin with the largest diameter, i.e., one whose chamber has the least clearance will bind against the chamber. This is the single pin holding the plug back. When picking the lock, you should feel that particular pin bind, while the rest are free to spring back and forth.

Once tension is applied and the binding pin lifted, the plug will rotate through a slight distance, allowing the chamber's pins to shear. The next binding pin with the smallest clearance stops the plug from further rotation. When the first pins are sheared, the driver pin rests on top of the plug to the side of the chamber while the key pin is free to fall back.

Since the tension is still engaged, you should then find and lift that pin till the plug rotates again by a small distance. Repeat this process until all the pins are sheared, and the picking would be termed as successful, but wait...

Modern locks demand modern approaches for successful picking. So, how do you increase your chance of hacking a modern lock by single pin picking?

You'll learn that next.

You may have read everything but still do not have a substantial success rate at picking locks. You need to learn the rules you might not be adhering to.

The rule of tension

every established lock picker knows how important tension is. As a beginner, this may be a little hard to grasp, but the earlier you master tension ranges, the faster you progress. It'll be much fun if you can tell the binding sequence, then if you seem to have picked the lock by random luck.

The following steps should help you break open almost any standard tumbler lock, by staying in the right torque range:

As you move to the next binding pin, you may need to increase the tension slightly if needed.

That's all you need to know when it comes to single pin picking. Just remember that different locks will produce different binding click sounds, and while older locks would be expected to be easier to pick, the click may not be clear due to accumulated dirt.

Now go buy your set of picks and put your skills to the test but first check whether owning such tools is legal in your state, before getting in the way of the law.

Comments will be approved before showing up.

Be the first to know about lockpicking tips and upcoming sales and promos. Get a 10% discount coupon when you subscribe!

Sign up to get special offers, Tips, News and Great deals